BLD is the manufacturer and installer of our Service Connection Seal plus Lateral (SCS+L) Cured-In-Place-Pipe (CIPP) lining system. ASTM 1216 compliant, the SCS+L is a CIPP lateral lining system that is installed from the main line sewer extending up the lateral to a specified termination point with or WITHOUT a cleanout. BLD manufactures our SCS+L in-house and installs the engineered product in the field. As the manufacturer and installer of the SCS+L system, we provide one point of contact for our work and product.

SCS+L CIPP Lateral Lining System

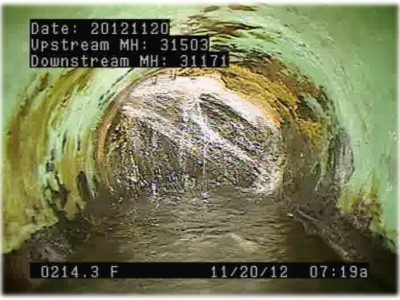

Before

After

Lunch & Learn

To learn more about how lateral rehabilitation can reduce I/I, submit the form below to set up a presentation at your location.

For more information on SCS+L, visit our Resource Room.

FAQ - CIPP Lateral Rehabilitation

What problems can defective laterals create?

One of the main problems of defective service laterals in the amount of rain derived inflow and infiltration (RDII) that can enter a sanitary sewer system through cracks or holes caused by root intrusion or aged pipes and/or damaged or poorly installed connection at the lateral and main interface. Many issues arise for municipalities when there is an excess of RDII rushing into the system, the most obvious being sanitary sewer overflows (SSOs), usually occurring during heavy rain events, causing the system to exceed capacity. However, there is a more insidious effect that RDII has on a collection system: the cost of treating the excess infiltration at the treatment plant for the municipality.

What problems can CIPP lateral rehabilitation solve?

BLD is the manufacturer and installer of the Service Connection Seal + Lateral (SCS+L) which provides a solution for several issues of a defective service lateral including:

- Eliminating root intrusion

- Providing a jointless CIPP liner that structurally replaces the host pipe

- Eliminating infiltration at the lateral / main connection utilizing a CIPP “full wrap” that forms a 360-degree circular liner within the inside diameter of the main, and the application of an engineered hydrophilic gasket as well as flow-able hydrophilic material that penetrates into cracks and crevices, thus providing a superior seal.

Why use hydrophilic material?

BLD’s hydrophilic material will expand in the presence of water and contract in the absence of water. When exposed to water, the hydrophilic materials will expand to prevent infiltration into the system. Third-party testing has proven the long-term effectiveness of BLD’s hydrophilic materials to eliminate infiltration while being subjected to prolonged hydration/dehydration cycling at varying hydro-static pressures.

Does installation of SCS+L require excavation or secondary access point?

BLD’s lateral cleaning, inspection, and installation are trenchless processes and do not require access to a clean-out. In addition, the equipment used to clean, inspect, and install service laterals is compact and, in most cases, does not require vehicular access to the private property, minimizing disturbances to businesses and homeowners. CIPP rehabilitation can be efficiently performed on laterals up to 80LF from the main without the need for a clean-out. (Typically, a clean-out is required for length greater than 80LF.)

How long does the CIPP lateral installation process take?

The typical time to rehabilitate a service lateral can vary depending on the variables within the later being repaired. A typical installation, from start to finish, generally takes no more than 4 hours. Shorter lengths can be completed in much shorter time frames.

Does BLD use licensed installers to rehabilitate service laterals with SCS+L?

We do not use licensed installers, only BLD employees that have undergone extensive training in safety, quality, and processes unique to the installation of the SCS+L.